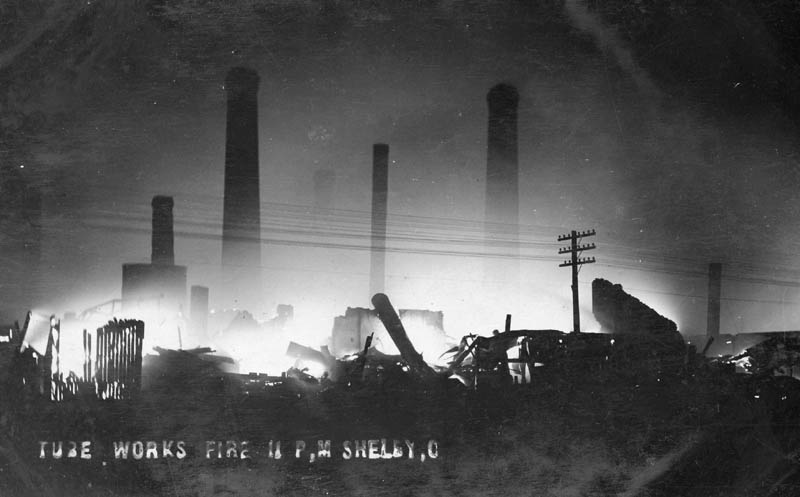

| Shelby’s livelihood, the Shelby Steel Tube Company, burned to the ground June 18, 1908 in just over an hour, leaving more than 800 men without jobs and the city potentially in ruins. |

| But by sheer determination, Shelbians raised funding and the plant was back in operation, and back under local ownership, within a year. |

|

|

|

- “The firemen would concentrate all their streams in one place in order to stop the mad rush but before a great while the flames would be whipping around them and they were compelled to drag the hose out and in many cases were glad to get out themselves. Several narrow escapes occurred as the men who have been employed there for years worked eagerly to stop the fire.”

|

|

|

| The committee of 25 |

|

| Committee gathers public support |

|

I.

The town of Shelby, had a great big Tube Works

But a month ago a fire came and took it all away,

And now they say what will you do about it,

Why, we’re going to build another and we’ll build it right away.

Right away! Right away!

We’re going to build another and we’ll build it right away.

Nicholson he came down here from Pittsburg,

We asked him his intentions, on the subject he was mum,

When we told him how we’d start another

He mopped his feverish brow, and said, “I guess that’s going some.”

Going some! Going some!

He mopped his fevered brow and said I guess that’s going some.

He told a Shelby man who interviewed him

He had a plan that he’d suggest and surely it would pay,

Said he, “you let us keep on making tubing

You start a factory making rakes and forks to pitch the hay.”

Pitch the hay! Pitch the hay!

You start a factory making rakes and forks to pitch the hay.

Hot air, you know, don’t count for much in Shelby

We’re going to raise the money it’s a cinch the people say,

We’re going to have an independent tube works

That will be a money maker and run both night and day.

Night and day! Night and day!

That will be a money maker and will run both night and day.

|

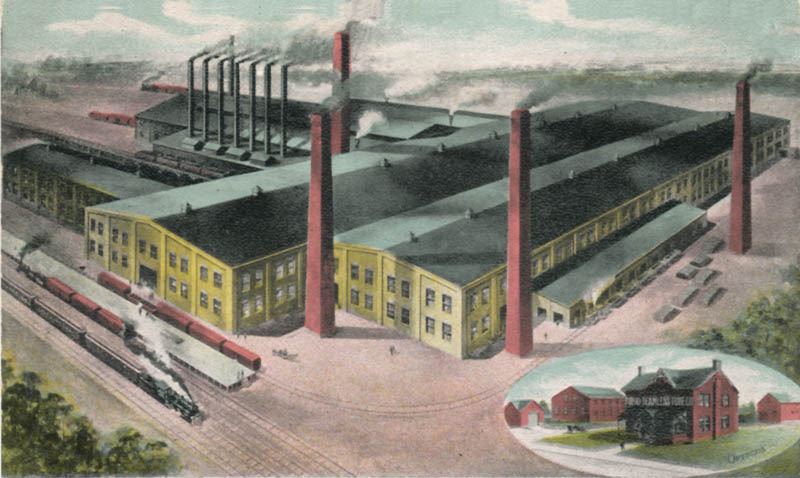

| $171,000 subscribed in three weeks |

|

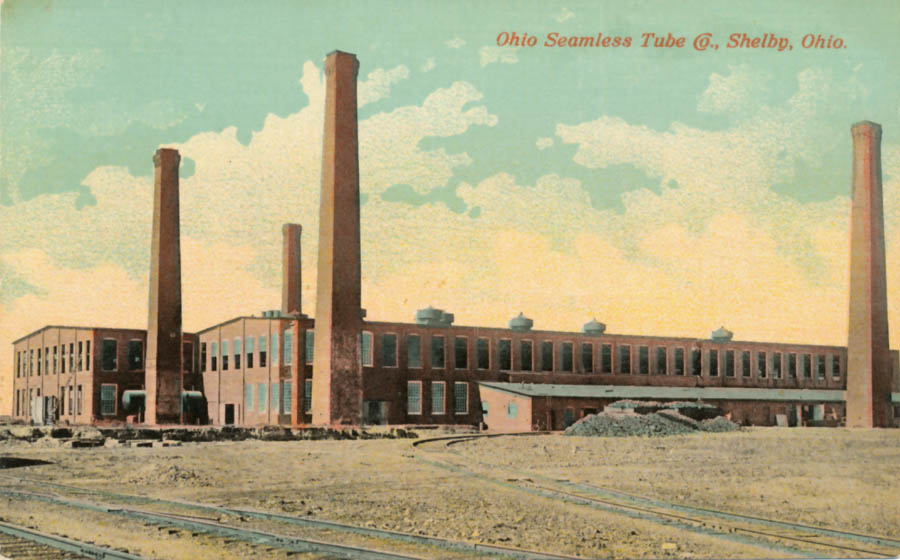

| Factory nears readiness |

|

|

|

photo c. 1909 |

|

|

photo c. 1910 |

Copyright © 2013 -2018